Why is the hard and rigid nature of epoxy thermosets not always beneficial?

Epoxy systems are recognised as hard and rigid due to the high degree of cross-linking. Although ideal in some instances, this can result in undesirable performance in others. In this context, it is key to appreciate hard, rigid thermosets are contrary to tough, flexible thermosets. When considering failure mechanics; toughness refers to the total energy required to cause failure over time. Toughness is therefore a colloquial expression for what engineers refer to as ‘the energy release rate’.

Hard and rigid thermosets may therefore have poor resistance to crack propagation and may be ‘notch sensitive’ with poor impact resistance. A lack of flexibility may result in a failure to accommodate movement and dimensional change of the substrate. A rigid adhesive may not perform well in peel or cleavage testing. The reason is that a degree of flexibility distributes stresses over a larger area thereby reducing stress concentration points.

It is often the objective of the product formulator to impart flexibility to the thermoset while maintaining other performance properties expected of an epoxy product. A number of epoxy-functional elastomeric resins have been developed which, when blended with conventional epoxy resins, impart elastomeric character. The trade-off is that in achieving properties such as flexibility and toughness, there is generally an accompanying reduction in thermal stability, chemical resistance as well as tensile, shear and compressive strength.

Carboxy-terminated acrylonitrile (CTBN) liquid rubber is a commonly used epoxy elastomer, as are polyethers, acrylates and elastomers with core-shell morphology. The formulator experienced in the use of these materials will appreciate that, while each has its merits, no single solution can be considered superior for all applications.

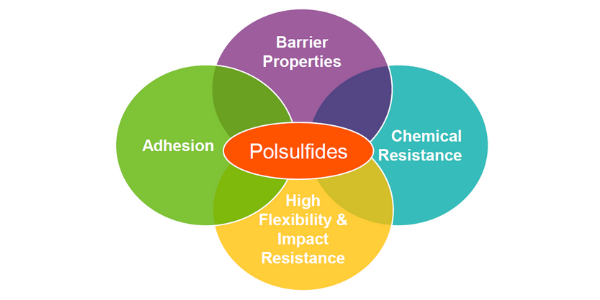

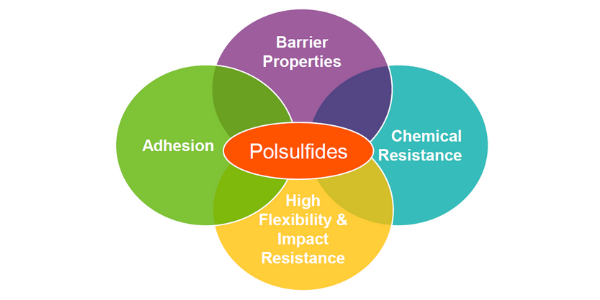

Thioplast™ polysulfide resins from Nouryon are amongst the most established resins used to impart flexibility and toughness to epoxy formulations. Thioplast™ resins are characterized by solvent and chemical resistance, low-temperature flexibility, low gas and moisture permeability as well as flex-crack resistance. They are used in epoxy coating and adhesive formulations to impart toughness, impact strength, chemical resistance and adhesion. Their gap-bridging properties are suitable as waterproof sealants for buildings, canals, sewage plants and motorway construction. In aerospace, flexibility and chemical resistance are maintained at sub-zero temperatures and are used to seal all parts of the aircraft fuselage, including fuel tanks.

Figure 1: Thioplast™ EPS epoxy-terminated polysulfides impart many benefits to epoxies including enhanced barrier properties, chemical resistance, flexibility and impact resistance and improved adhesion.

Thioplast™ EPS epoxy-terminated polysulfides

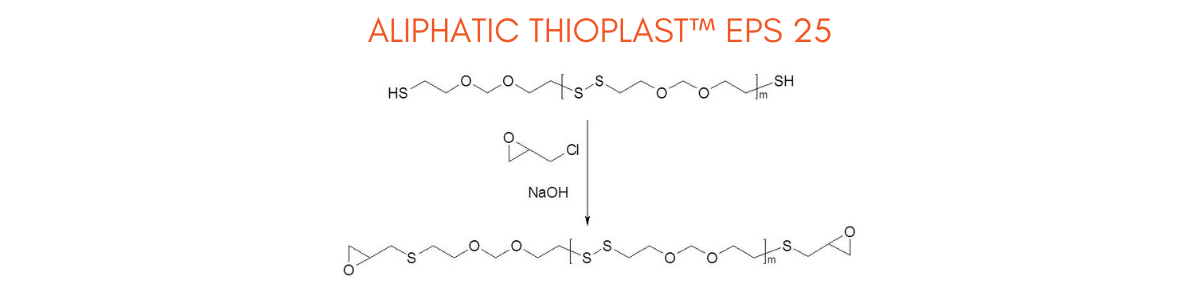

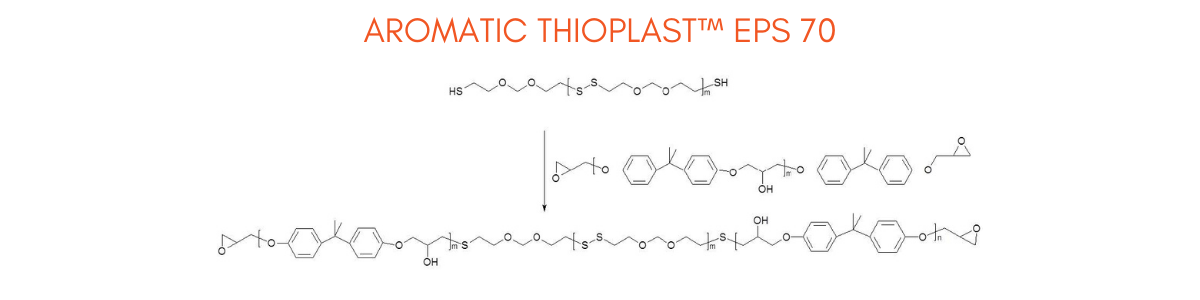

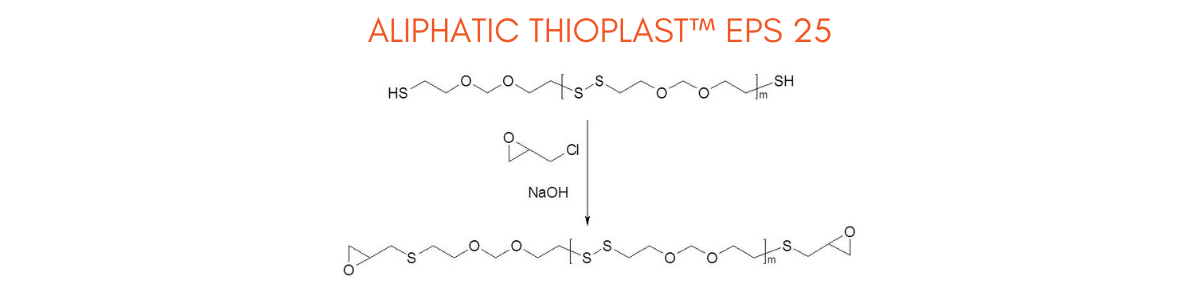

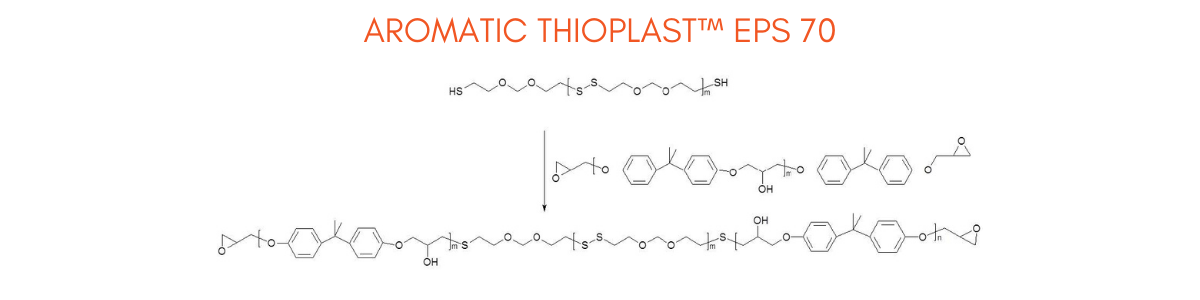

Thioplast™ EPS are epoxy-terminated polysulfides and are the reaction products of thiol-terminated polysulfides with epoxy functional species. Thioplast™ EPS is available as two types of epoxy-functional polysulfide; aromatic and aliphatic. The chemical structure of an aliphatic grade (Thioplast™ EPS 25) and that of an aromatic grade (Thioplast™ EPS 70) are shown in Figure 2 and Figure 3. Aliphatic grades are more suitable for exposure to sunlight but cure times are slow at ambient. Aromatic grades have cure rates similar to conventional epoxy resin. The addition of epoxy terminated polysulfide to the resin component of a two-pack epoxy system is typical of a class of crack-bridging epoxy coatings for concrete protection.

Flexible epoxy coating for the protection of concrete from chemical attack are applied to secondary containment and chemical holding areas as well as chemical drains, channels and retaining walls. The flexibility and chemical resistance of the coating prevent contamination of soil and groundwater by ensuring the coating remains intact in the event of the concrete substrate cracking underneath.

Figure 2: Synthesis of aliphatic Thioplast™ EPS 25 from a low viscosity polysulfide which is reacted with epichlorohydrin at high pH in a NaOH based environment. Aliphatic types like Thioplast™ EPS 25 and Thioplast™ EPS 35 are well suited to outdoor applications due to their colour stability however they are slower curing than aromatic types.

Figure 3: Synthesis of aromatic Thioplast™ EPS 70 from a polysulfide and Bisphenol A/F diglycidylether (DGEBA/F) forms a DGEBA/F functionalized polysulfide based block copolymer. Thioplast™ EPS 70 is suitable for indoor and some outdoor applications and cures quicker than the aliphatic types Thioplast™ EPS 25 and Thioplast™ EPS 35.

Improved chemical resistance with Thioplast™ EPS

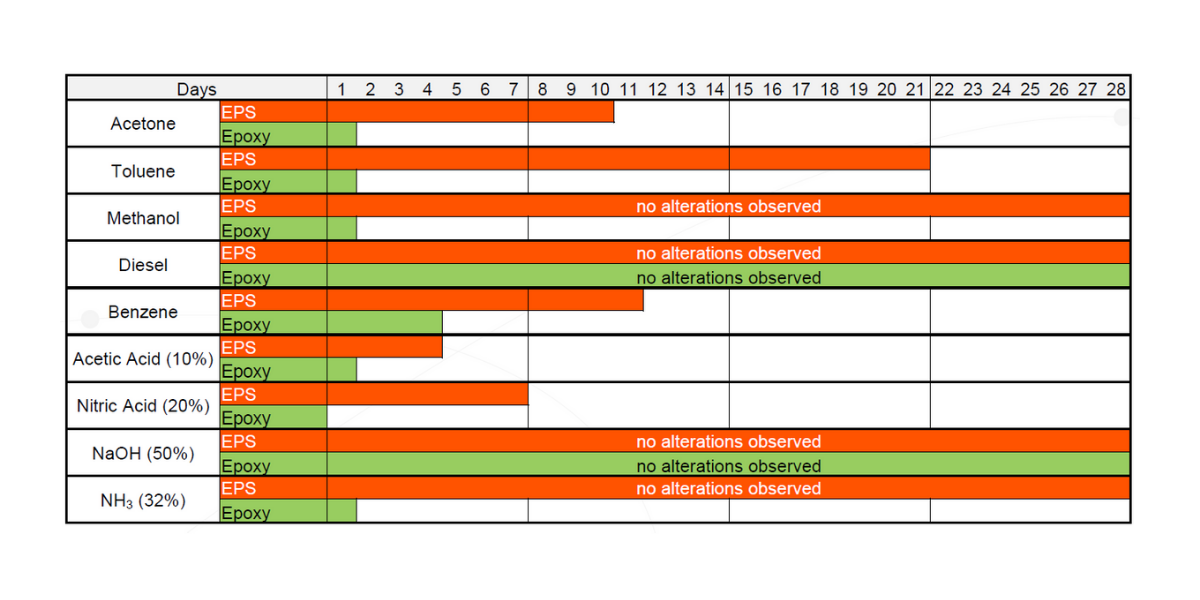

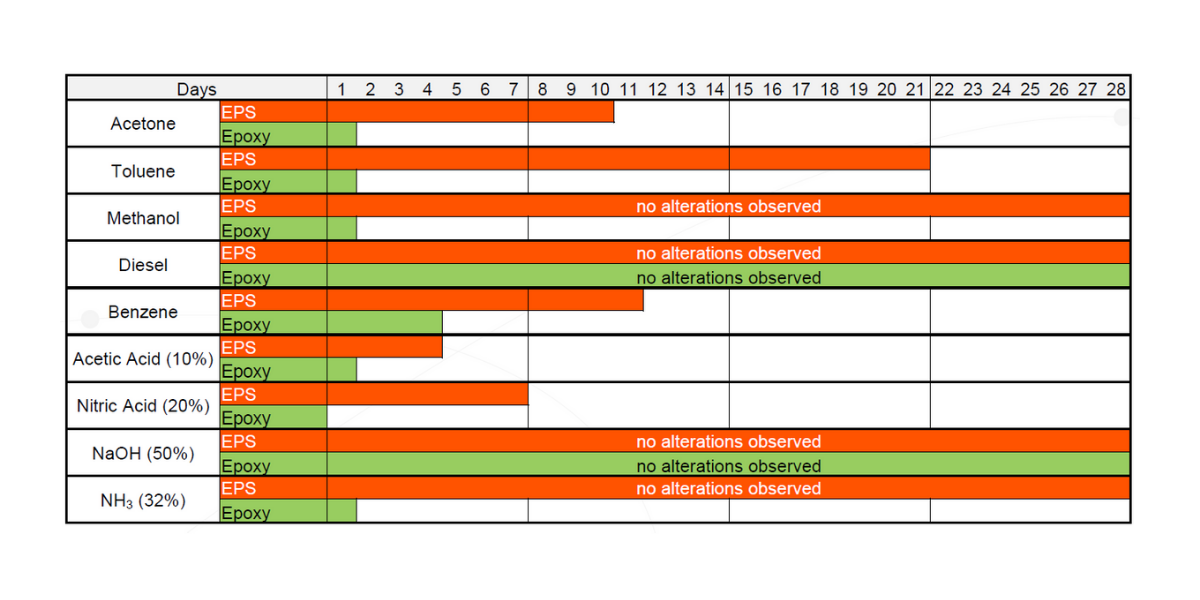

A starting formulation for a crack-bridging epoxy coating based on Thioplast™ EPS 70 is shown in Table 1 which resulted in significant improvements to chemical resistance versus a conventional epoxy coating (Figure 4).

Binder

|

|

| D.E.R. 331 (Bisphenol A resin) |

20.0 |

| Epilox 13-21 (Difunctional reactive diluent) |

5.0 |

| Thioplast™ EPS70 |

60.0 |

Additives

|

|

| Defoamer |

0.5 |

| Aluminium silicate |

5.5 |

| Magnesium silicate |

4.0 |

| Carbon Black |

5.0 |

| Total |

100.0 |

Curative

|

|

| Aradur 2964 (cycloaliphatic amine) |

31.0 |

Table 1: Formulation for a crack-bridging epoxy coating based on Thioplast™ EPS 70.

Figure 4: Incorporation of Thioplast™ EPS 70 into an epoxy coating significantly improves the chemical resistance and is therefore ideal for use on surfaces exposed to fuels and aggressive cleaners.

Improved flexibility, crack bridging and impact resistance with Thioplast™ EPS

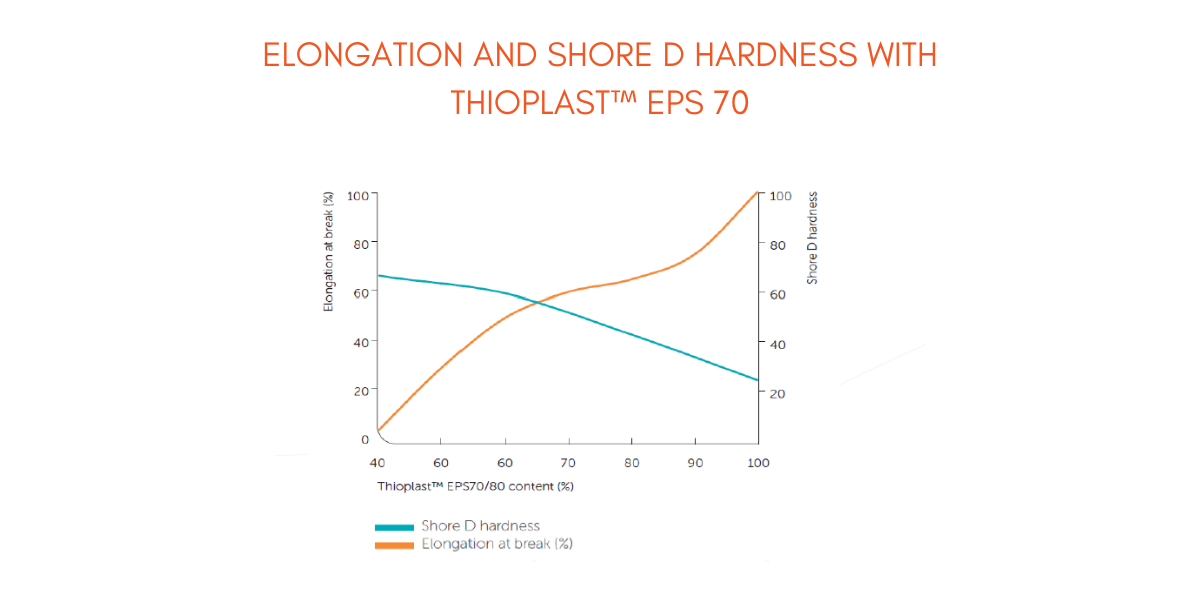

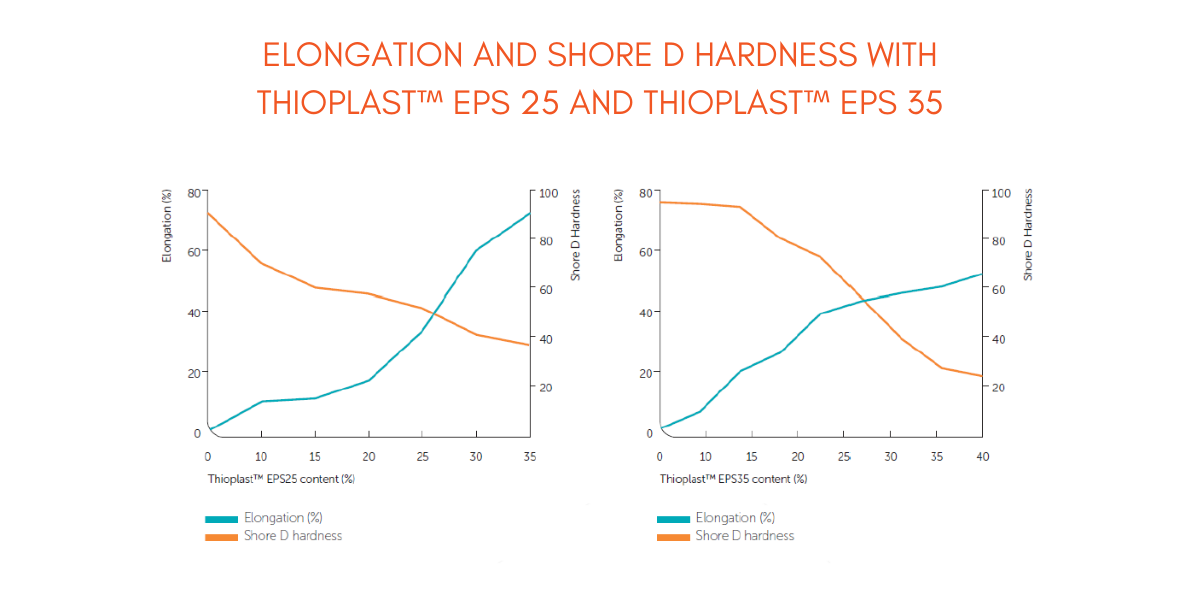

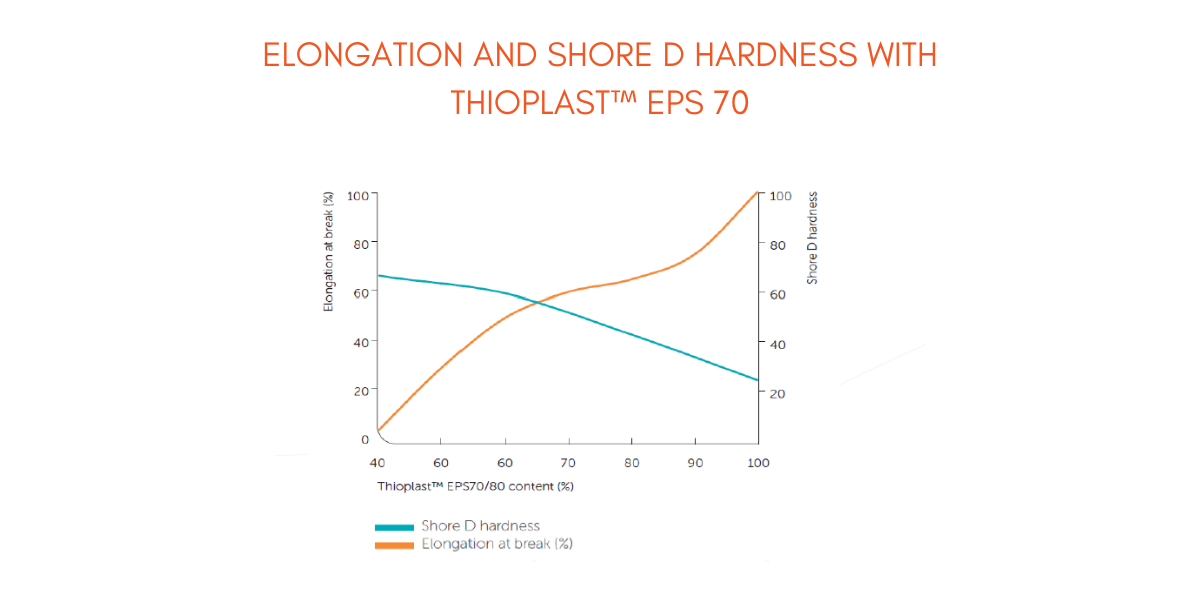

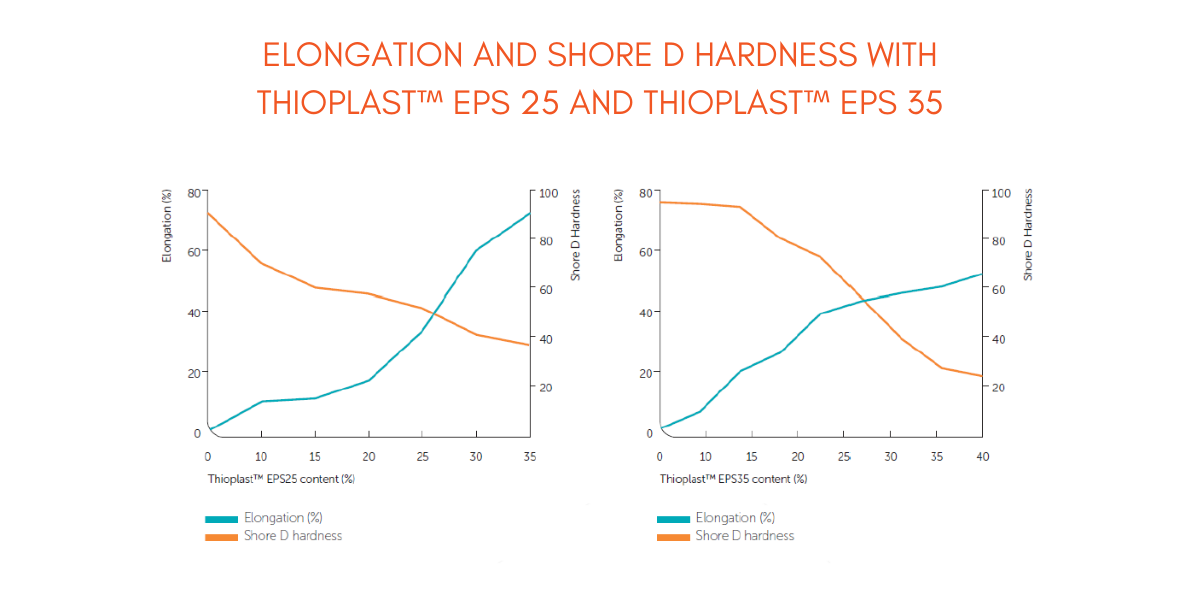

Increasing levels of Thioplast™ EPS up to 80% by weight of the total resin formulation has a significant effect on the final cured properties of the epoxy coating. Elongation at break improves significantly with both aromatic (Figure 5) and aliphatic types (Figure 6) and increasing addition levels also resulting in decreasing Shore D hardness and improved crack resistance. The aliphatic types, Thioplast™ EPS 25 and Thioplast™ EPS 35, result in high elongations even at low addition levels as can be seen in Figure 7.

Figure 5: Increasing additions of aromatic Thioplast™ EPS types results in increased elongation and decreased Shore D hardness. In an epoxy formulation of a standard Bisphenol A/F epoxy-based resin and Thioplast™ EPS 70, elongation was six times higher than that of pure aromatic epoxies.

Figure 6: Aliphatic Thioplast™ EPS resins dramatically increase flexibility; even at concentrations as low as 10%, high elongations are achieved, in particular with Thioplast™ EPS 35. As expected Shore D hardness also decreases with increased Thioplast™ EPS content.

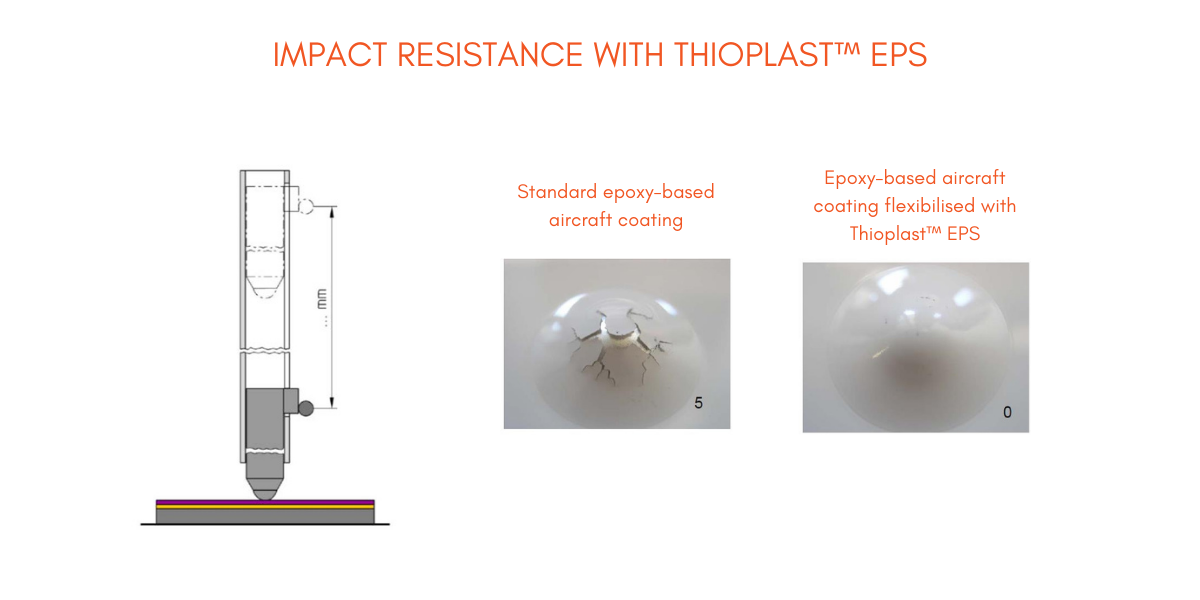

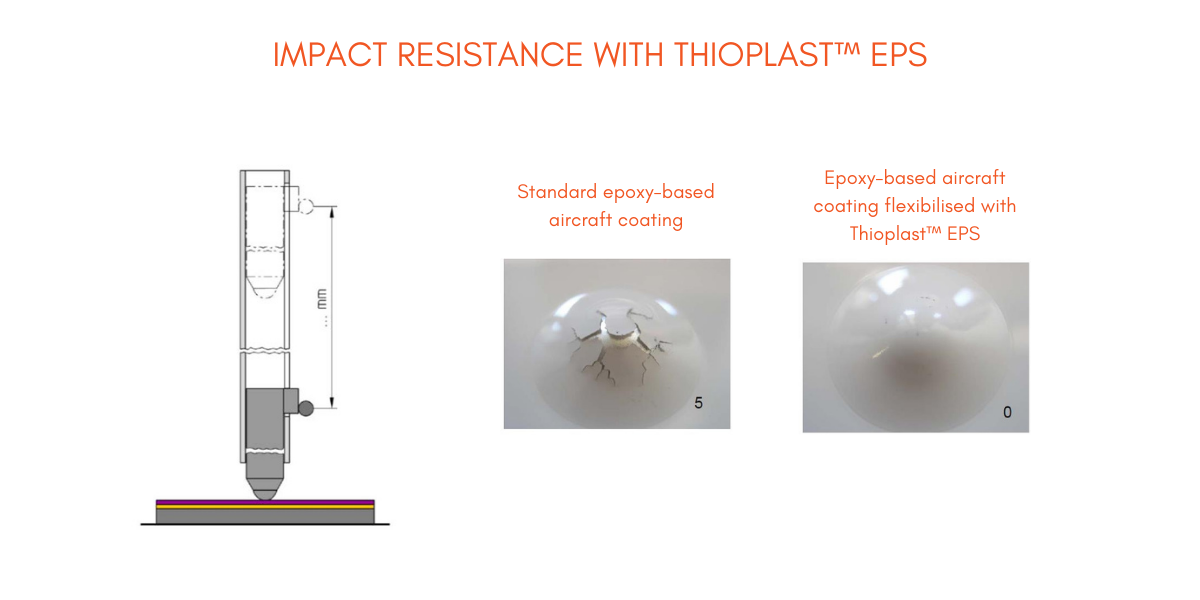

The incorporation of Thioplast™ EPS into an epoxy resin also results in improved impact resistance as it is possible to formulate very flexible coatings with simultaneous high hardness. As seen in Figure 7, a 55% addition of Thioplast™ EPS 70 into a standard epoxy formulation results in a coating able to meet the highest chemical and mechanical demands.

Figure 7: Incoporation of 55% Thioplast™ EPS 70 into an epoxy coating results in a hard-wearing yet flexible coating able to withstand impacts several times that of the standard epoxy.

Self-healing properties with Thioplast™ EPS

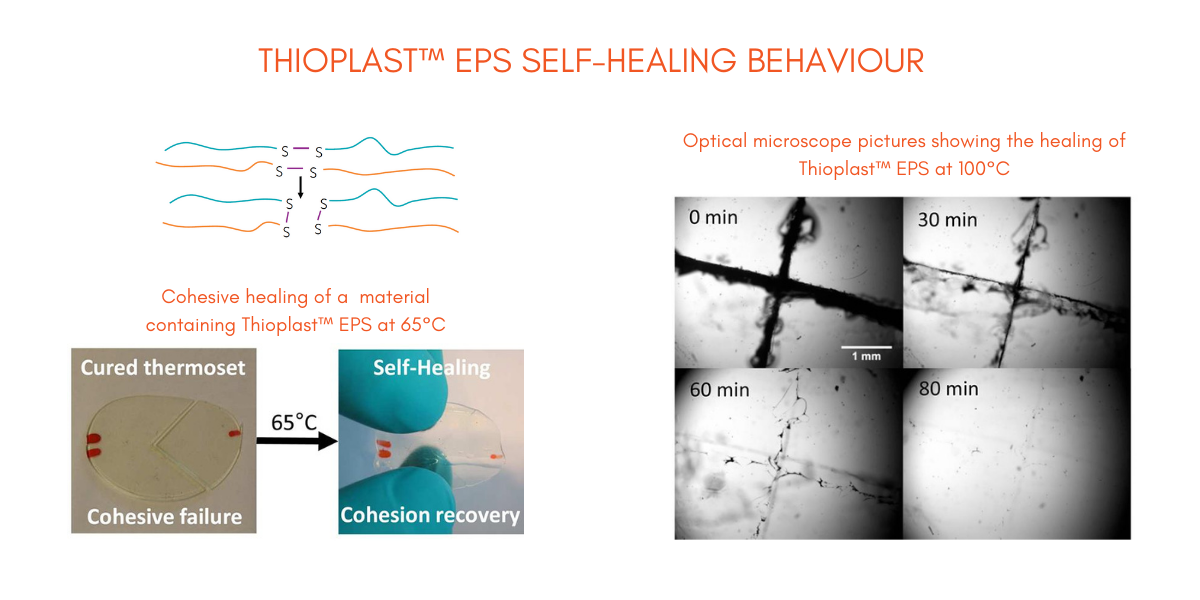

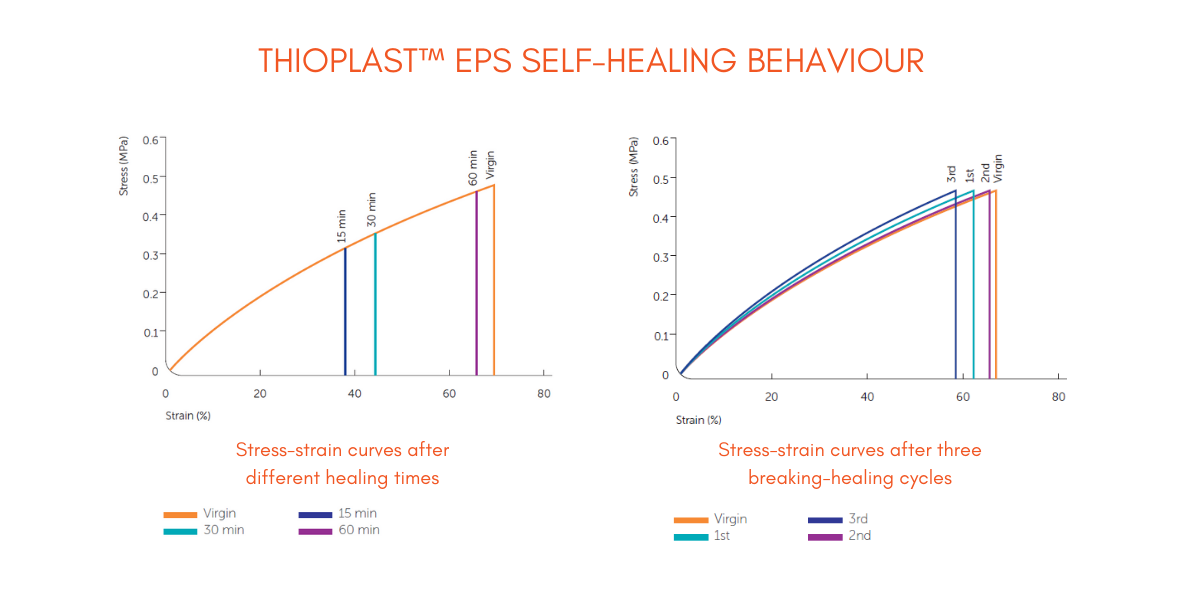

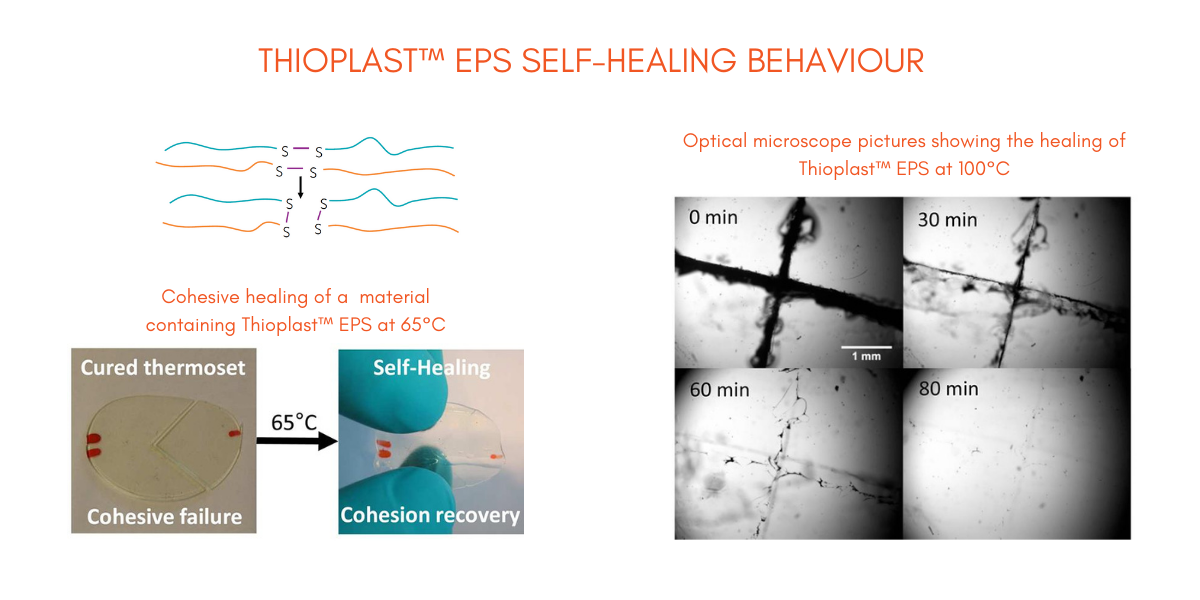

Thioplast™ EPS resins are capable of demonstrating self-healing behaviour. As can be seen in Figure 8, the sulfur-sulfur (S-S) bonds are capable of intermolecular sulfur exchange reactions and will continuously rearrange leading to excellent self-repair capabilities. Self-repair is catalysed at higher temperatures and as expected, increased concentrations of polysulfide result in a greater level of strength (%) recovery.

Figure 8: Materials containing Thioplast™ EPS demonstrate self-healing behaviour due to the polysulfide backbone.

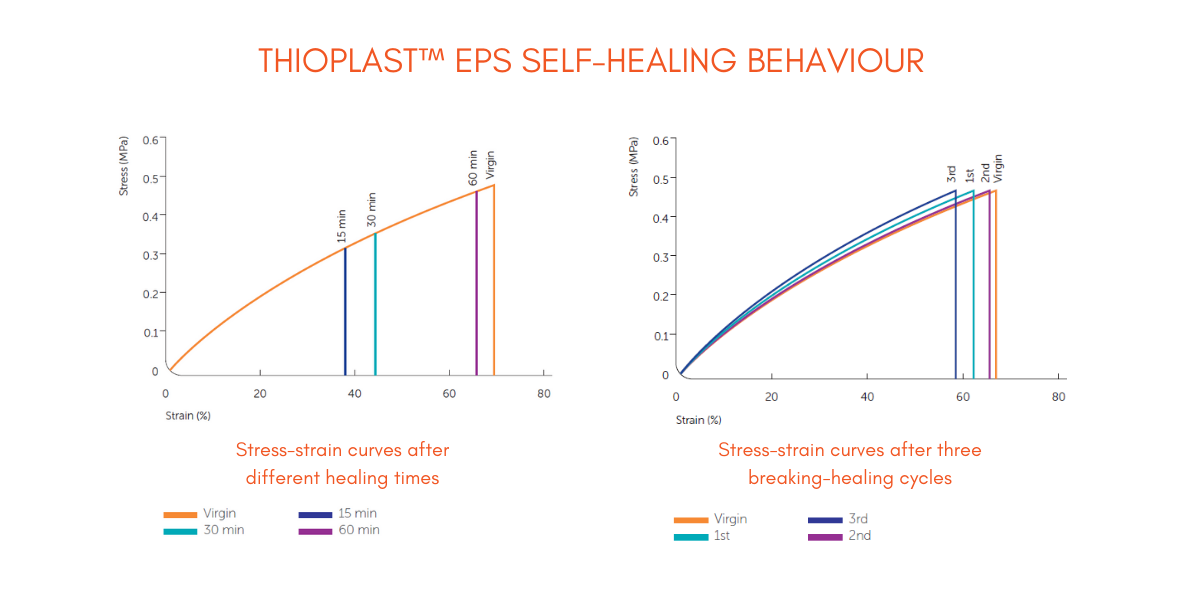

Materials containing Thioplast™ EPS polysulfides can self-repair multiple times without loss of strength and no systematic decrease in consecutive breaking-healing cycles is observed (Figure 8). Strength recovery is also rapid; in tensile tests carried out by Nouryon, a 60% recovery was observed after only 15 minutes contact time and after 60 minutes strength was comparable to the original sample. Interestingly all repaired samples show similar stress-strain curves indicating that the healed samples have similar elastic properties as the virgin material.

Figure 9: To measure self-repair capacity of Thioplast™ EPS polysulfides, samples were prepared for tensile strength testing. After breaking, samples were immediately put back into contact and heated at 60 °C to self-repair. Different healing times (left) and repeated breaking-healing cycles (right) were tested with the samples. Not only does Thioplast™ EPS regain 60% of its strength after only 15 minutes, repeated breaking-healing cycles does not lead to a decrease in strength.

Summary

Conventional epoxy thermosets are highly cross-linked polymers with high temperature and chemical resistance but low mechanical flexibility. Thioplast™ polysulfide polymers are used to impart significant flexibility and toughness which result in improved performance characteristics in some applications. For further insight and for recommendations for your formulation, contact your Lawrence Industries account manager to discuss your requirements.